*m*e*n*u | 206

-

-

*G *m*e*n*u-09i | Plans-IAC

-

|

To view some ALTERNATE ways

of building these controls, see

Ted

Ansley’s Flickr photo album, showing several

versions of indoor control units that he has built.

-

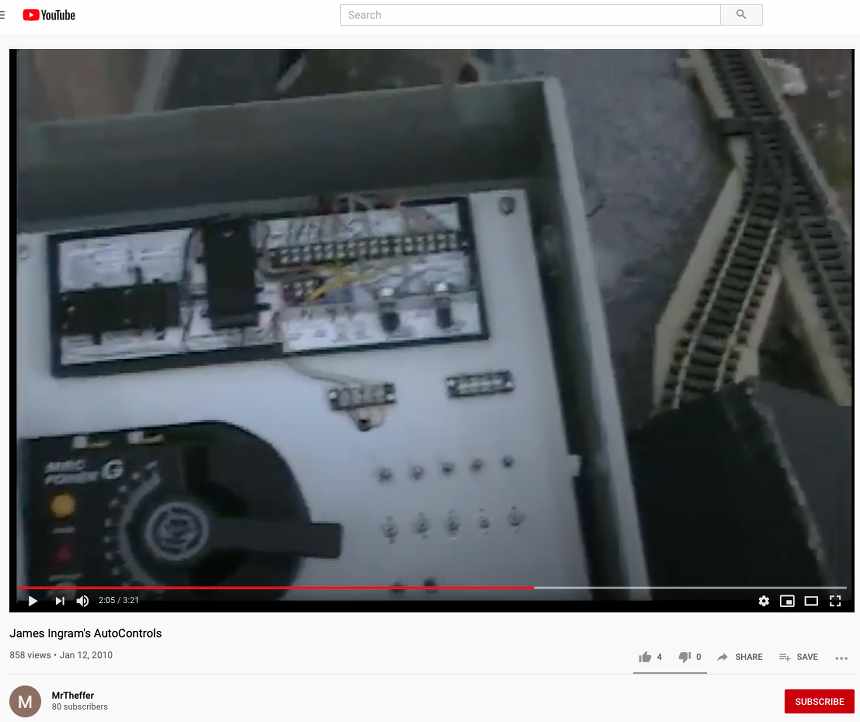

This

Youtube

video by Tim Heffernan This

Youtube

video by Tim Heffernan

shows a Model 206 Control Unit, controlling an outdoor

railroad.

But keep in mind that DIRT getting in the turnouts, can be a

problem outdoors.

-

-

-

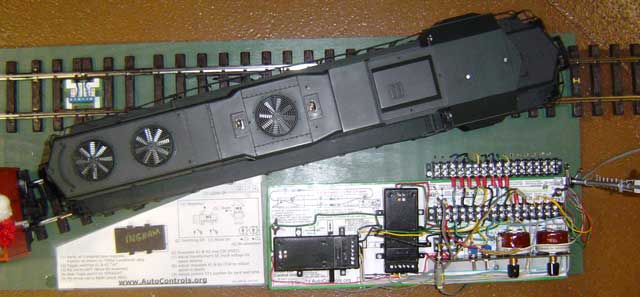

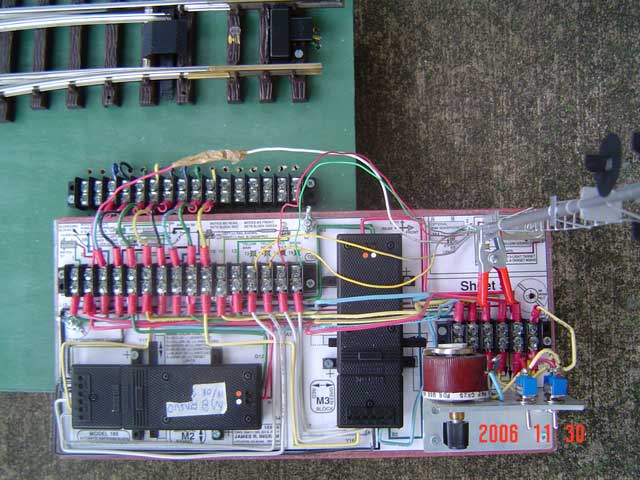

Photo 1 - A 2-track Automatic

Yard is shown operating on the Loose

Ties MRC

multi-gauge display, Dec 2006 in Selinsgrove Pa.

-

(If you care

about the details: Technically the above unit is a

model 205 Control Unit (aka Model 165) operating

on a Model 206 track unit. The below photos show

the new Model 206 control unit, which is almost

the same, except it has a 2nd rheostat, is a

slight narrower and longer.)

|

Purpose

Of

These Controls

These

2-track automatic yards seem to be the most

popular of the automatic controls (the others

being the single-track and the 4-track units).

These 2-track yards are typically used to

operate 3 trains on a single loop.

They seem to

be very effective at ENTERTAINING crowds on

display layouts like the one shown above.

Their simple electromechanical parts allow

most railroaders to understand how they

work, and keep them operating properly on

the display.

Principle

of

operation:

- The red block

holds 2 trains in the yard, until the 3rd

train on the mainline gets about 2/3 around

the mainline (wherever the T2 track contact

is positioned) and "releases" one of the

trains in the yard.

- The train on

the mainline then enters the yard on the

empty track.

- This

sequencing continues so all 3 trains take

their turn running around the layout.

|

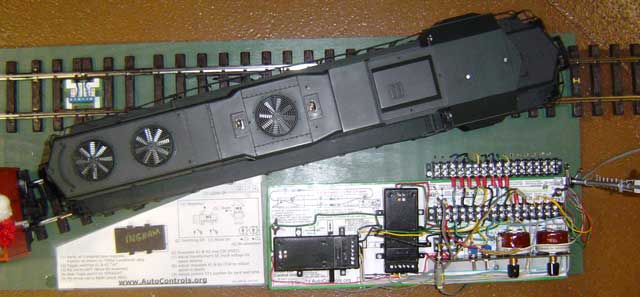

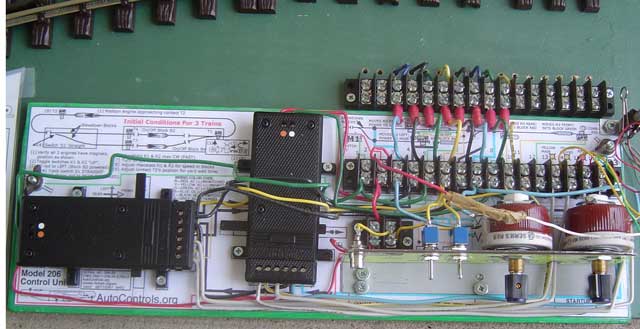

Photo 2 - Front view - Model

206 Automatic Yard -- plans drawn Feb 2007.

|

Components

To

Install In A Layout

The

above photo shows the yard and associated

components, ready to install in a display

layout.

- Track

Sections -- The front & rear track

sections (on the green plywood).

- Loose

Track -- The track shown between the

front and rear track sections, is used

to make whatever length of yard will

fit the layout space.

- Signal

Light -- The 4-light target signal -

shown already attached to the front

track unit.

- AC

Power -- The white box on the lower

left is a Radio Shack 18v/24v

transformer, used to provide 18 volts

AC power to the control unit.

- T2

Track Contact -- The small black

object on the lower right is the LGB

'T2' track contact, which is position

1/2 to 2/3 around the mainline. (The

T1, T3, & T4 track contacts are

attached to the front track unit).

- Rear

Switch Wire -- The duplex wire that

connects the rear switch to the

control unit is bundled up at the rear

switch motor.

|

Photo 3 - Front view - Model

206 Automatic Yard.

A USA Trains GP-38 waits on the left siding, and an

Aristo Craft RS3 waits on the right mainline. An LGB

0-4-0 is the 3rd engine, out on the mainline on the

other side of the layout.

Photo 4 - Side View.

Photo 5 - Rear View.

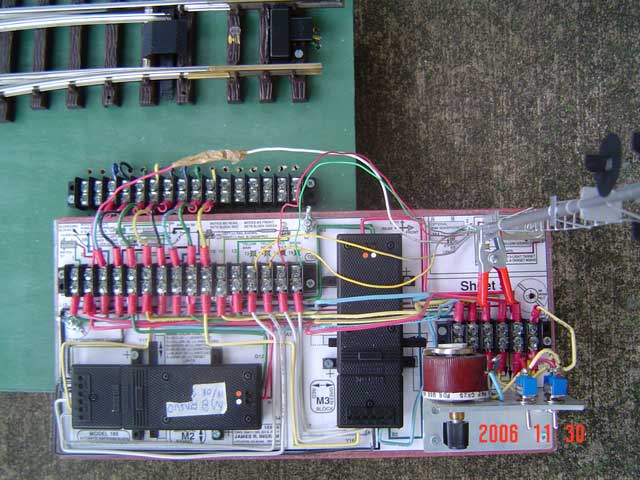

Photo 6 - Top View, showing the

GP-38 on the front switch.

Note the front switch has no motor. The trains just push

it into the correct position.

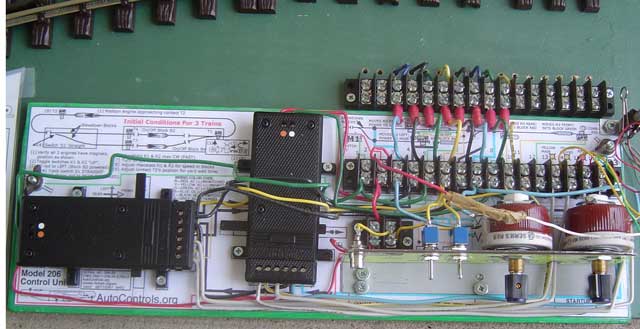

Photo 7 - Close-up of the

Control Unit.

Click

Here to view a LARGER

photo of the above assembled Control

Unit

Click

Here to view a LARGE photo of the

"template" that you see underneath the parts.

|

<

|

Template

Note

the control unit is built on top of a

"plastic-laminated template". This template

guides positioning of parts and wires during

construction, and provides built-in "hookup

documentation" and "startup documentation"

when the unit is in use on displays.

Components

The

primary components from left to right are

- LGB switch

motor M2 - routes power to either siding

or mainline

- LGB switch

motor M3 - turns power on and off in

startup block

- Blue toggle

switch K1 - controls power to switch motor

M2 (switching function)

- Blue toggle

switch K2 - controls power to switch motor

M3 (blocking function)

- Rheostat R1

- controls voltage in slowdown block

- Rheostat R2

- controls voltage in startup block.

Simplicity

The

advantages of these simple electromechanical

controls are:

- No

electronic circuits to malfunction, or

electronic vendors to go out of business

- The

throw-rods of the switch motors allow

operators to visually determine the

"state" of the control unit (siding or

mainline powered, stop block red or green)

- The

throw-rods of the switch motors allow

operators to easily set "initial

conditions" which the unit is started up,

or when it is depowered and just operated

as a "dumb track".

|

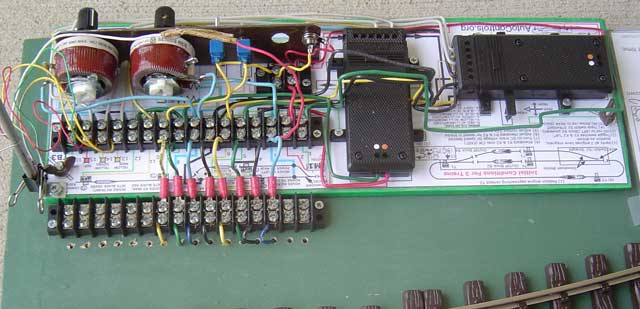

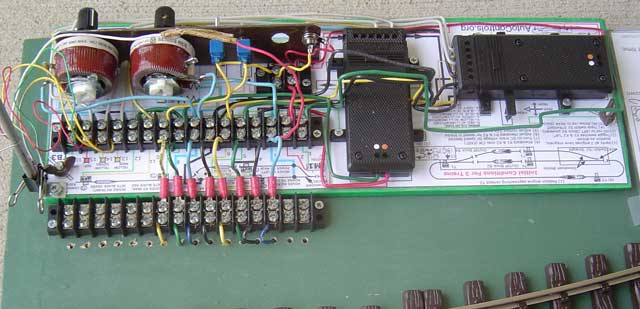

Photo 8 - View of the control

unit and template from the other side.

- The diagram in the lower left --

between the 2 terminal blocks -- shows the hookup

connections between the control unit and the track.

- The diagram in the lower right --

is an "initial conditions" sketch that reminds

operators how to start up the system.

Photo 9 - The "Initial Conditions"

sheet reminds operators how to start the unit up at the

beginning of the day's operations. The drawings have

additional instructions for powering down the siding or

the block or the complete controls.

Photo 10 - The

Shiloh Signals ( ShilohSignals.com (website gone??) )

4-light target signal indicates all "states" of the

control unit.

Photo

11 - Same photo as Photo 2 above, but rotated and

dimensions added.

Photo 12 - This photo shows

the OLDER Model 205 Control Unit (aka 165).

The earlier Model

205 - drawn in 1994 -is almost the same, except it has

a single rheostat, and is a slight shorter and wider.).

Photo 13 - Designer James

Ingram -- shown Dec 2001 with an early design Model 202

(aka Model 163), built in 1992.

-

|

MPEG Movies - showing

the above Model 202-Track Unit

Note

these OLD movies were made in 2003, before

the Quicktime videos were made

- MPEG

Movie 1

-- 15 seconds, 320 pixels -- shows above

2-track Automatic Yard

- MPEG

Movie 2

-- 60 seconds, 160 pixels -- shows above

2-track Automatic Yard

Note the

general principle of operation:

- The

switching block holds 2 trains in the

yard, until the 3rd train on the

mainline "releases" one of the trains in

the yard.

- The train

on the mainline then enters the yard on

the empty track.

- This

sequencing continues so all 3 trains

take their turn running around the

layout.

|

-

-

This page

created Mar 2007; modified 4/12/2010

(20F17)) by

(bottom include)

JamesRobertIngram.com

, Williamsport

PA, Apache Junction AZ

|

This

Youtube

video by Tim Heffernan

This

Youtube

video by Tim Heffernan