|

||||||

-

|

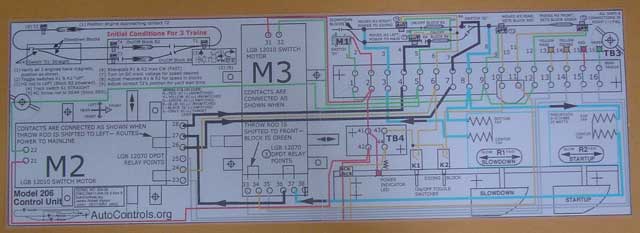

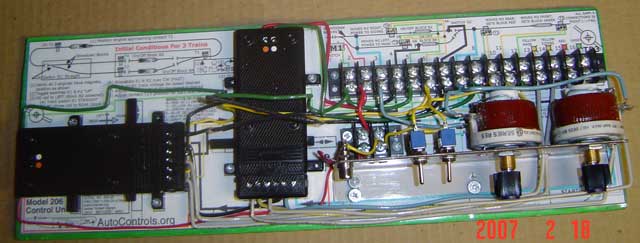

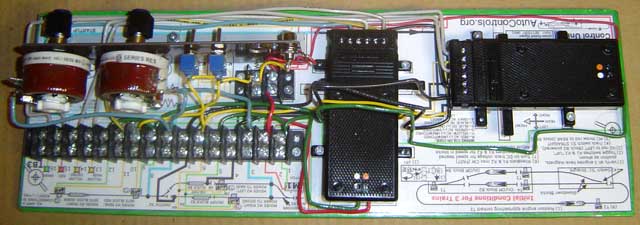

Photo 2 - Template cut from drawing

Sheet 9, plastic-laminated front and back.

I know this,

because I built my early pre-1994 units

without templates, and I am always having to

SEARCH for drawings to see how something on

them connects. With the template, you have

all the "hook up" information you need,

right on the control unit.

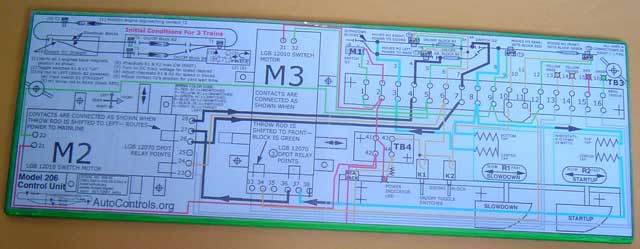

Photo 4 - You can use the drawing in

Sheet 9 Fig. 9.2 as a template

Photo 5 - You can use the drawing in

Sheet 9 Fig. 9.3 as a template

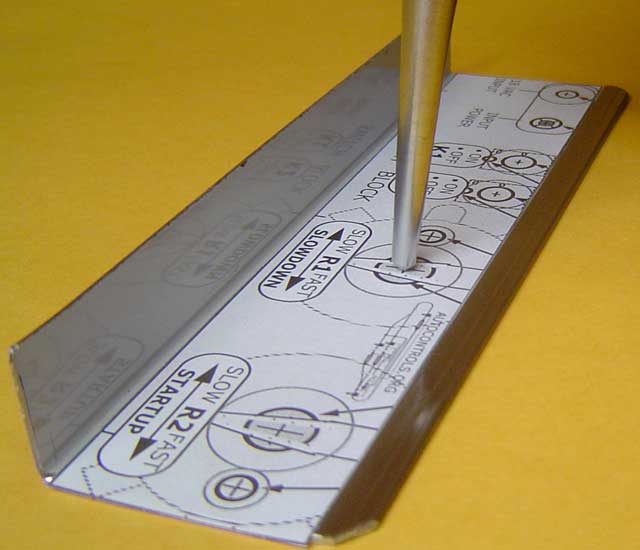

About The Angle You can use

the 1-1/2" x 1-1/2" x 1/8" thick aluminum

angle that you can find in the home stores.

Ideally you would like to cut the bottom

side from 1-1/2" down to about 1/2", so it

fits in the available space, and does not

cover the wires on the template.

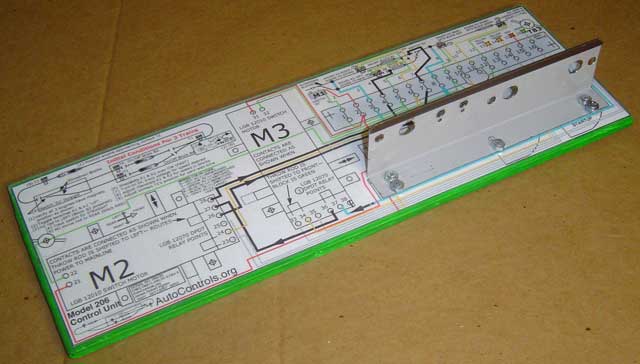

Photo 6 - Rheostat bracket attached to base.

Photo 7 - Base with all parts

attached, ready to begin wiring.

About Wire

Gauges About Wire

Assembly Order Connect red,

yellow, & green (AC) wires 2nd. Connect any

red, yellow, green & blue wires that

connect to parts on the rheostat bracket

LAST. (If you connect these first, then you

have to "fish" the other wires underneath,

which is cumbersome.)

Photo 8 - Control Unit with all wires attached.

Photo 9 - Control Unit viewed from the other side

|

|||||